CLOSE ✖

How to Freeze Dry Rose and Hydrangea Petals?

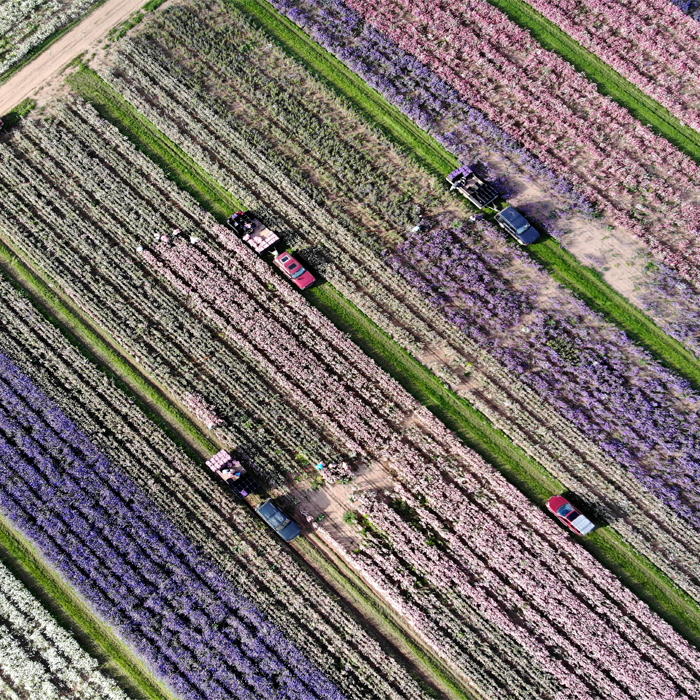

It has been an exciting week at LSF Wholesale as we’ve had an arrival of a brand-new freeze dryer.

This sparkling clean freeze dryer is 300cm long and 90cm wide, which means it’s able to hold 14,500 rose heads and 2500 hydrangeas heads per individual load.

We now have not one or two, but three freeze dryers on site. Adding a third freeze dryer to our collection is a great step in moving our freeze-drying production forward. It will allow LSF Wholesale to process more rose and hydrangea heads each year, which will take our freeze-dried petal supply to the next level.

What is freeze-drying?

Freeze-drying is the only way to extract moisture from a flower head. Once the flower head is completely freeze-dried, it can then be depetaled for its glorious petals. It’s this freeze-drying process that allows the rose and hydrangea petals you see on our wholesale site to keep their shape and colour for months on end.

How do freeze-dryers work?

The freeze-drying process itself is a complicated, but interesting one. It requires a lot of professional skills, as damaging the product can happen very quickly with just one small mistake.

Before the process of freeze-drying even begins, the hydrangea and rose heads need to be cut from the stem and placed on metal trays.

The freeze-drying machine has two special chambers: the specimen chamber (top) and the condenser chamber (bottom). Once the trays have been filled, they can be placed inside the specimen chamber, it’s then the freezing process begins and the roses or hydrangeas are frozen to -40 degrees.

It’s at this point, the vacuum pump comes into operation and the drying process comes into force. The vacuum pump extracts the vapour from the roses or hydrangeas, converts it into ice-crystals and then deposits it into the condenser chamber. The condenser chamber works at -55 degrees, so it’s much colder than the specimen chamber. Over a few days, a layer of ice starts to appear in the condenser chamber, which is then removed via defrosting.

It’s good news when the condenser chamber stops producing ice, this means the process is complete and the specimen chamber can be opened.

The freeze-drying processing time depends on what product is inside the dryer. Hydrangeas heads take up to 20 days, whilst rose heads 30 days. From the heads hitting the freeze-drying, to them being depetalled, the completed process takes around a month.

By carrying out this rigorous freeze-drying process with great care and technique, LSF Wholesale is able to produce perfectly freeze-dried rose and hydrangea petals in bulk to both the UK and international market.

Please see our colourful collection of wholesale freeze-dried rose and hydrangea petals here.

If you are business that wishes to purchase wholesale freeze-dried rose or hydrangea petals, then you can apply for an account here. Alternatively, if you have any questions, please get in contact via phone or email.

Behind the Scenes